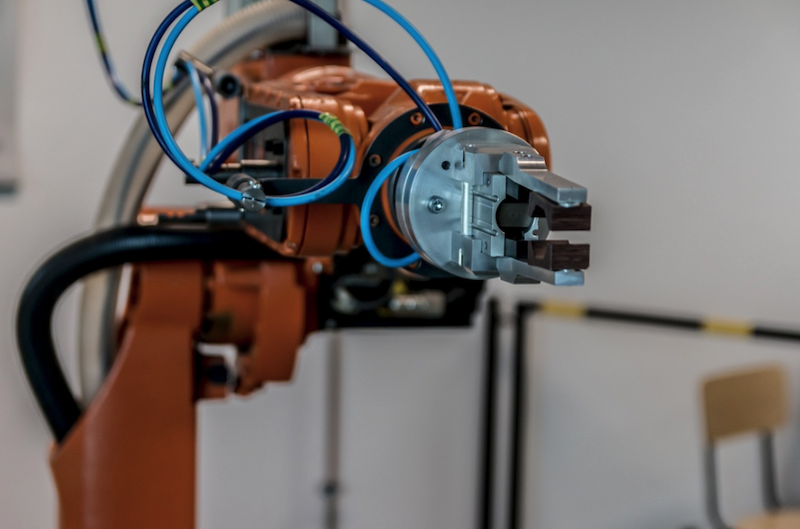

Despite advances in technology such as smart CNC controls and industrial robots, the fundamental importance of tool geometry in machining processes cannot be overstated. As automation and artificial intelligence reshape manufacturing floors, it remains critical that cutting tools are designed with precision to ensure optimal performance. This article explores how tool geometry influences machining efficiency, particularly in environments utilizing robotic systems.

Understanding the Role of Tool Geometry

As robots increasingly handle the loading of parts and CNC systems adapt feeds and speeds dynamically, it may seem that the role of tooling has diminished. However, the reality is that the actual cutting still occurs at the point where a carbide tool meets the metal. It is here that tool geometry plays a decisive role in determining whether a smart manufacturing process yields successful results.

Key factors such as helix angles, rake angles, flute counts, and corner designs fundamentally affect cutting forces, heat generation, chip flow, and surface finish. If these elements are not optimized, even the most sophisticated systems will struggle to achieve stable and productive cuts. This is especially relevant in environments where robots operate unattended, where the choice of end mill can significantly impact production outcomes.

The Impact of Geometry on Process Efficiency

In a typical high-mix job shop, automation might dictate that one cell machines stainless brackets in the morning and aluminum housings in the afternoon. Although CNC parameters can be programmed to switch seamlessly, the true effectiveness of this setup is largely influenced by the geometry of the tools used. Research indicates that even minor adjustments in edge radius or rake angle can lead to substantial variations in cutting forces and surface quality.

A recent study focusing on machining quality found that optimizing tool micro-geometry can reduce cutting forces and enhance surface finish, leading to improved consistency and tool longevity across various parts. Such findings highlight the sensitivity of processes to geometry choices, establishing that a tool cannot simply be categorized by its size alone. For example, a high-helix, polished three-flute tool will perform differently than a four-flute general-purpose tool, particularly in specific materials like aluminum.

In robotic applications, the importance of process robustness is amplified. Unlike human operators who can detect and respond to irregularities, robots continue to load parts without adjustment. Effective tool geometry serves as a safeguard against silent failures. For instance, using a small corner radius when machining hard stainless steel can minimize stress at the tool tip, effectively prolonging tool life and maintaining dimensional accuracy.

Similarly, flute count and chip space are vital considerations. In confined pockets where chip evacuation is crucial, a two- or three-flute design can facilitate efficient chip removal, whereas a four-flute design might lead to overheating and chatter, ultimately compromising the machining process. Robots do not compensate for these failures; they merely reflect the quality of the geometry choices made.

Strategies for Optimal Tool Geometry

For manufacturers already investing in advanced CNC and robotic technologies, enhancing tool geometry decisions is a logical next step. One approach is to standardize “tool families” based on material and operation rather than only diameter. For example, for aluminum machining, specifying high-helix, polished three-flute tools with small corner radii for both roughing and finishing can yield better outcomes. Conversely, for harder steels, defining a low-helix, multi-flute design with appropriate edge preparation and coatings is essential.

When integrating new parts into robotic cells, it is imperative to review not only the feeds and speeds but also the helix angle, flute count, and corner geometry of primary cutters. Simple questions can guide these decisions: Will the flute configuration effectively clear chips from the pocket? Is the corner design robust enough for the expected engagement? Does the edge preparation align with the material and coolant strategy?

Collecting data on which tool geometries consistently produce superior surface finishes or reduce overload alarms is vital. Such insights should inform standard practices for future parts, creating a library of geometries that support the automated processes manufacturers aim to scale.

In conclusion, while smart CNC controls and industrial robots significantly enhance manufacturing capabilities, the foundational role of tool geometry remains critical. Recognizing geometry as an essential design decision rather than an afterthought will maximize the benefits of advanced technologies on the shop floor. By prioritizing tool geometry, manufacturers can ensure their automated processes are both efficient and effective.