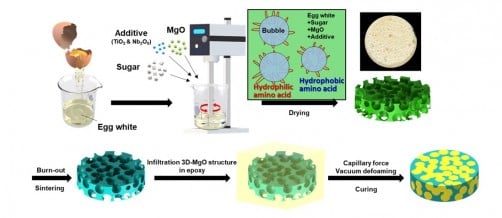

A research team led by Dr. Hyun-Ae Cha from the Korea Institute of Materials Science (KIMS) has successfully developed a high-performance, eco-friendly composite material designed for heat dissipation. This innovative material utilizes a protein foaming process based on egg whites to create a three-dimensional structure of magnesium oxide (MgO), significantly enhancing thermal conductivity.

The composite material demonstrates thermal conductivity up to 2.6 times higher than conventional heat-dissipating composites, achieving an impressive thermal conductivity of 17.19 W/m·K. This breakthrough comes as the demand for effective thermal management increases, particularly in high-performance electronic devices and electric vehicles (EVs), where overheating can lead to serious safety issues.

Advancing Thermal Management Technology

As electronic devices become more compact and powerful, the heat they generate rises, necessitating advanced thermal management solutions. For EVs, inadequate battery cooling can result in performance degradation and even fires, underlining the need for precise thermal interface materials (TIMs). Traditional TIMs are often limited by their production methods, which involve mixing thermally conductive fillers into a polymer matrix. This process can lead to uneven distribution and hinder thermal performance.

To overcome these challenges, Dr. Cha’s team adopted a novel approach using egg-white proteins. By leveraging the proteins’ ability to expand at high temperatures, the researchers created a dense, interconnected network of MgO particles. This structure facilitates continuous thermal pathways, enhancing heat transfer efficiency and overall performance.

The resulting composite not only outperforms commonly used materials like aluminum oxide (Al2O3) but also surpasses nitride-based heat-dissipating materials while remaining lightweight and cost-effective. By integrating the composite with epoxy resin, a polymer often used with thermal fillers, the team produced a practical material suitable for real-world applications.

Impact on Korea’s Thermal Management Market

The commercialization of this technology is poised to significantly impact Korea’s thermal interface materials market, which is estimated to exceed KRW 200 billion annually. Currently, this market relies heavily on imports, making local advancements in thermal management materials critical for enhancing national technological self-reliance.

Dr. Cha emphasized the dual benefits of this research: “Through the protein foaming–based process, we can produce high–thermal–conductivity materials in an eco-friendly and cost-effective way.” She further noted that this study exemplifies the potential for developing lightweight, high-performance heat-dissipating materials.

The research was funded by the National Research Foundation of Korea (NRF) as part of its Nano Materials Technology Development Program. Results were published on May 28, 2023, in the esteemed journal Advanced Science, where it featured as the cover article for Volume 12, Issue 33.

KIMS, the institute behind this groundbreaking research, plays a vital role in the development of comprehensive materials technologies in Korea. Its contributions extend across various fields, including research and development, inspection, testing, evaluation, and technology support, reflecting its commitment to advancing the nation’s industrial capabilities.