Graphene, often hailed as a revolutionary material, has unique properties such as exceptional strength and electrical conductivity. However, despite significant interest over the past decade, many graphene-based technologies remain confined to laboratory settings. Researchers have encountered challenges, particularly in the functionalization of graphene, which is essential for expanding its applications. A recent study, conducted by a team led by Chamalki Madhusha at Monash University and published in ACS Sustainable Chemistry & Engineering, highlights a novel approach to producing functionalized graphene materials with a focus on sustainability.

Researchers frequently face difficulties in making graphene usable due to its limited solubility in common solvents. This limitation necessitates complex and often environmentally damaging functionalization methods. Conventional techniques, such as nitrogen doping, can generate significant waste and require toxic precursors, high-temperature treatments above 600 °C, and multiple processing steps. These processes compromise the environmental integrity of graphene production, raising concerns as sustainability becomes an increasingly critical issue in materials science.

Innovative Mechanochemical Approaches

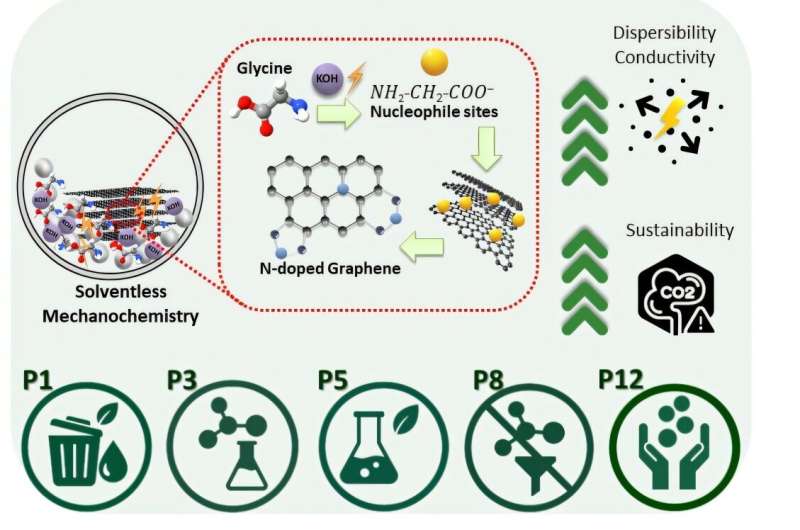

The research team turned to mechanochemistry, a method that employs mechanical forces to drive chemical reactions without the need for solvents. This technique has gained traction in the field of green chemistry due to its potential to reduce chemical waste and energy consumption. By utilizing a ball-milling process, the researchers successfully functionalized graphite with a bio-derived nitrogen source, specifically amino acids, under ambient conditions. This solvent-free method resulted in the production of nitrogen-doped graphene nanoplatelets (N-GNPs) while maintaining control over the material’s properties.

The benefits of this approach are substantial. The N-GNPs produced exhibited high electrical conductivity alongside excellent dispersibility, addressing two significant challenges in graphene processing. The research team achieved an impressive material yield of approximately 80%, a notable accomplishment for solid-state synthesis methods. Additionally, the environmentally friendly process resulted in a significantly lower E-factor, a metric that measures the amount of waste generated per unit of product. By eliminating solvents and high-temperature steps, the overall energy consumption was markedly reduced.

Enhancing Material Performance and Sustainability

The incorporation of nitrogen atoms into the graphene lattice alters its electronic properties, enhancing electrical conductivity and chemical reactivity. The study demonstrated that the N-GNPs retained high structural quality while benefiting from the functional improvements brought about by nitrogen doping. When utilized as nanofillers in composite systems, these materials showed promising potential for improving electrical, thermal, and mechanical properties.

The implications of this research extend beyond graphene itself. The compatibility of N-GNPs with vitrimers, a type of polymer known for its mechanical strength and reprocessability, is particularly noteworthy. When integrated into vitrimer matrices, N-GNPs can facilitate self-healing properties, enhance overall material strength, and improve conductivity—all while preserving the stability of the polymer network. This development paves the way for innovative applications, including repairable coatings and recyclable composites that prioritize both performance and sustainability.

The emphasis on sustainability in materials design is crucial in today’s environmental landscape, where industries like electronics, aerospace, and energy storage increasingly prioritize eco-friendly practices. The mechanochemical approach showcased in this research exemplifies how advanced materials can be produced with reduced environmental impact, aligning with evolving regulatory and safety standards.

Looking forward, the research team is committed to expanding this green synthesis method to incorporate other dopants and explore scalable manufacturing techniques. The ultimate goal is to enhance the development of advanced materials while simultaneously promoting sustainable production methods, addressing the growing demand for functional materials in various industries.

The findings from this study underscore the importance of rethinking conventional production methods in materials science. By integrating green chemistry principles from the outset, researchers can make significant strides toward reducing waste and energy consumption, paving the way for a more sustainable future in advanced materials manufacturing.