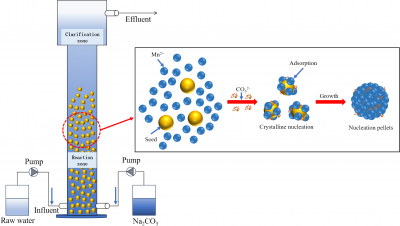

A recent study has unveiled an innovative method for efficiently recovering manganese ions from hydrometallurgical tailings water. The research highlights the effectiveness of the Nucleation Crystallization Pelleting Process, showcasing its potential to significantly mitigate resource wastage while addressing environmental challenges associated with mining by-products.

The study demonstrates that this process can recover high concentrations of Manganese (Mn) ions, a crucial component in various industrial applications, including batteries and steel production. By transforming tailings water into a valuable resource, the process not only enhances resource efficiency but also minimizes the ecological footprint of mining operations.

Process Overview and Benefits

The Nucleation Crystallization Pelleting Process operates by inducing crystallization within the tailings water, allowing for the selective extraction of manganese ions. This method stands out due to its high recovery rate, estimated to exceed 90% under optimal conditions.

Notably, the process can be implemented in existing mining operations without extensive modifications, making it a practical solution for companies aiming to enhance their sustainability efforts. The ability to recover valuable materials while reducing waste aligns with global trends towards more sustainable mining practices.

Environmental concerns surrounding the disposal of tailings have prompted a need for innovative recovery solutions. Mining companies face increasing pressure from regulatory bodies and the public to adopt practices that reduce their environmental impact. The findings of this study provide a viable pathway for industries to transform waste into valuable resources.

Implications for the Mining Industry

As the demand for manganese continues to rise, particularly in the context of renewable energy technologies, the significance of effective recovery methods cannot be overstated. This study suggests that the Nucleation Crystallization Pelleting Process could play a critical role in securing a sustainable supply of manganese.

Companies implementing this method may not only improve their bottom line but also enhance their reputation among environmentally conscious consumers and investors. The ability to turn waste into profit represents a significant shift in the mining landscape, promoting a circular economy within the industry.

Overall, the research underscores the importance of innovation in addressing both economic and environmental challenges. By adopting advanced recovery techniques, the mining sector can align itself with global sustainability goals while ensuring the responsible use of natural resources.

In conclusion, this study presents a promising solution for manganese recovery from hydrometallurgical tailings water. The potential for high efficiency and practical applicability makes the Nucleation Crystallization Pelleting Process a noteworthy development in the quest for sustainable mining practices.