A collaborative research team led by Dr. Gyujin Song from the Korea Institute of Energy Research (KIER), along with Dr. Kwon-Hyung Lee of the University of Cambridge and Professor Tae-Hee Kim from the University of Ulsan, has developed an innovative dry-process manufacturing technology for secondary battery electrodes. This advancement addresses significant limitations present in conventional electrode fabrication techniques.

The newly devised method creates a dual-fibrous structure within the electrode, utilizing both thin “thread-like” and thick “rope-like” fibers. This structure effectively tackles issues related to low mixing strength and performance degradation that have historically plagued dry processes. Traditional electrode manufacturing methods are classified into wet and dry processes, with the wet process being more common due to its reliability and performance advantages. However, it relies heavily on toxic organic solvents, which contribute to environmental pollution and high production costs.

By contrast, the dry process eliminates the use of solvents, facilitating quicker processing times and reducing energy consumption. The challenge faced by researchers in dry electrode fabrication has been the limited range of binder materials available, primarily using polytetrafluoroethylene (PTFE). PTFE, known for its heat and chemical resistance, is widely recognized as Teflon, a common material in non-stick cookware.

To overcome these challenges, the research team maintained the conventional PTFE binder material but restructured it to create a dual-fiber architecture. This involved a multi-step process that separates the addition of the binder into two distinct stages. Initially, a small amount of binder is introduced to create a fine fibrous network that connects the active material and conductive additives. Subsequently, additional binder is added, forming a thicker fiber structure while preserving the integrity of the initial network.

The results are promising. The fine fibrous network ensures uniform dispersion of the electrode materials, enhancing the electrochemical reactions within the battery. The thicker fibers provide mechanical stability, significantly increasing the strength and durability of the electrodes—key attributes necessary for mass production.

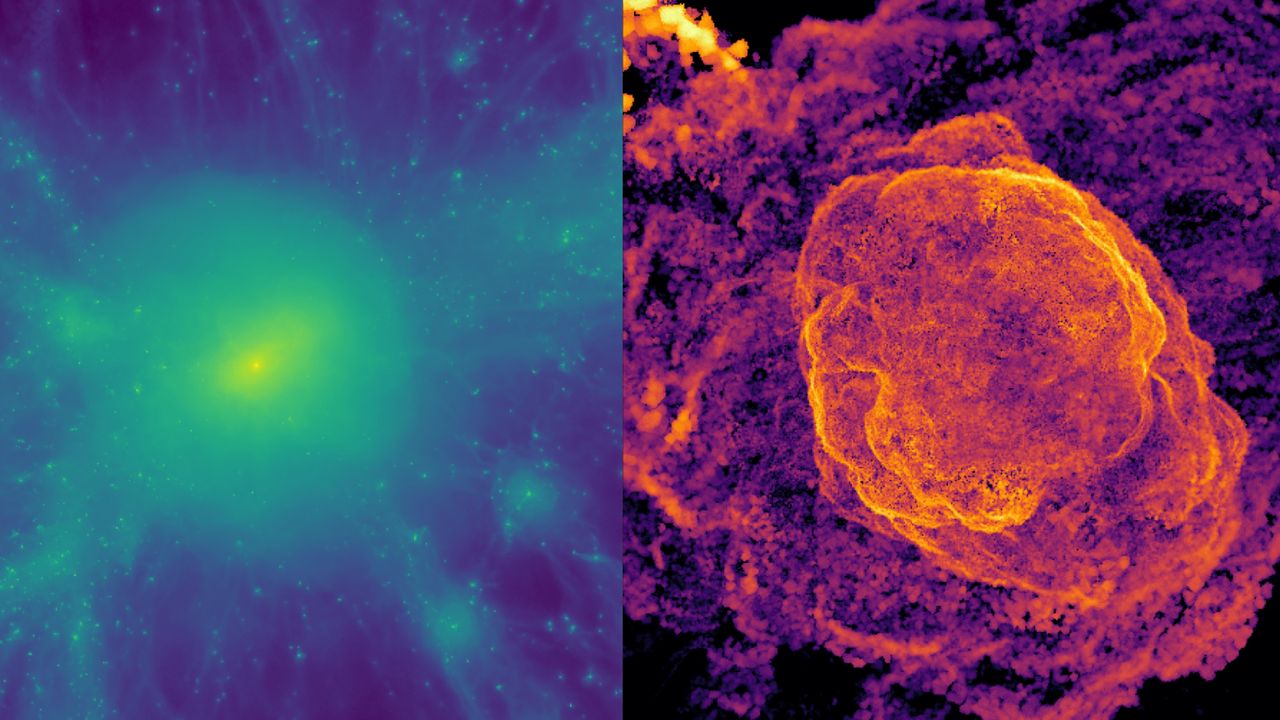

Analysis through electrochemical reaction-resistance mapping showed that the electrodes exhibit consistent reaction kinetics and resistance characteristics, minimizing energy loss during operation. This improvement helps prevent performance degradation and extends the overall lifespan of the battery cells.

In testing, the dry electrodes achieved an impressive areal capacity of 10.1 mAh/cm2. A pouch-type lithium metal anode cell constructed with this technology registered an energy density of 349 Wh/kg, representing a nearly 40% increase compared to conventional electrodes, which typically average around 250 Wh/kg. In addition, a pouch cell utilizing a graphite anode reached an energy density of 291 Wh/kg, approximately 20% higher than that of a wet-process cell under equivalent conditions.

Dr. Song emphasized the significance of this research, stating, “This study is highly significant in that we have established an original process technology capable of simultaneously resolving the two core challenges of dry electrodes: electrochemical uniformity and mechanical durability. We expect it to not only enhance the cost competitiveness of the secondary battery industry but also be applicable to electric vehicles and energy storage systems (ESS), which require high energy density.”

This innovative research was supported by the Ministry of Science and ICT through its “Global TOP Research Program” and “Creative Allied Project.” The findings were published in the September 2023 issue of Energy & Environmental Science, a leading journal in the energy and environmental sector.