A startup named Orbital Arc has announced the development of a groundbreaking spacecraft thruster that could be up to 40 percent more power efficient than current models. This innovative thruster uses naphthalene as its fuel, offering a significantly lower cost—around $1.50 per kilogram—compared to the typical $3,000 per kilogram for xenon. The new design promises to reduce the thruster’s weight to just one-eighth of traditional systems, making it suitable for even the smallest low-earth orbit satellites.

At the helm of this initiative is Jonathan Huffman, the founder of Orbital Arc, who describes the device as being compact enough to fit on a chip. “We can go from a thruster that’s a few inches across and several kilograms to a thruster on a chip that’s about an inch across and has the same thrust output,” Huffman explained. This advancement could provide substantial savings for satellite operators dealing with space debris and for mission planners sending probes to distant planets.

Innovative Design and Functionality

Traditional thrusters operate by generating and expelling plasma, which pushes the spacecraft in the opposite direction. In the case of Hall thrusters, a magnetic field traps electrons, ionizing a noble gas like xenon. Orbital Arc’s approach deviates from this method, leveraging a unique combination of MEMS microfabrication techniques and naphthalene.

Huffman, who has a background in biotech consulting and a passion for science fiction, initially conceived this technology while designing fictional spacecraft for a video game. His research into propulsion systems revealed limitations in existing ion thrusters that he believed could be overcome. “If a mission requires more thrust, its thruster needs to be heavier. But there’s a point at which adding more mass negates all of the benefits you can get from extra thrust,” he noted.

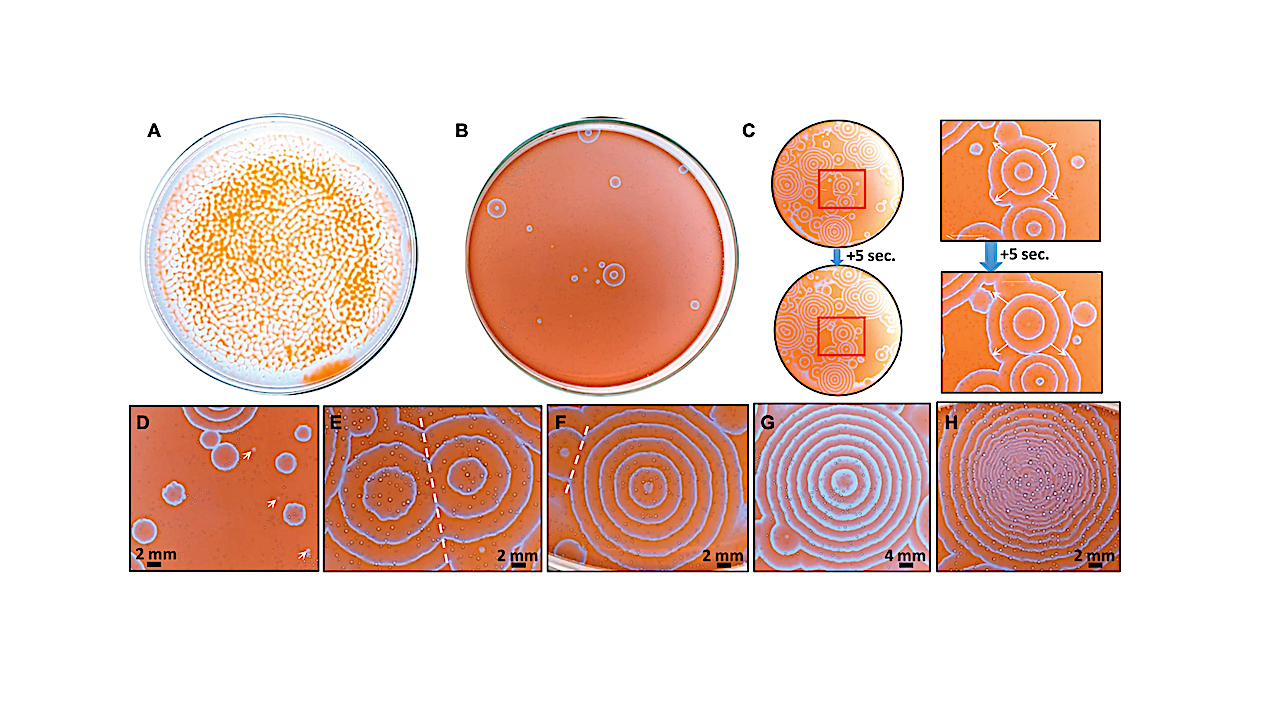

Each thruster from Orbital Arc features a chip embedded with millions of positively charged tips that ionize naphthalene. As the naphthalene molecules pass these tips, they become polarized, which enables the release of electrons and the creation of ions. These ions are then expelled into space, propelling the spacecraft forward. This design avoids the energy losses associated with plasma generation, resulting in a claimed 30 to 40 percent improvement in power efficiency.

Recent demonstrations have showcased the potential of this technology, with just six of Orbital Arc’s tips generating three times more ion current than an array of 320,000 tips from a team at MIT.

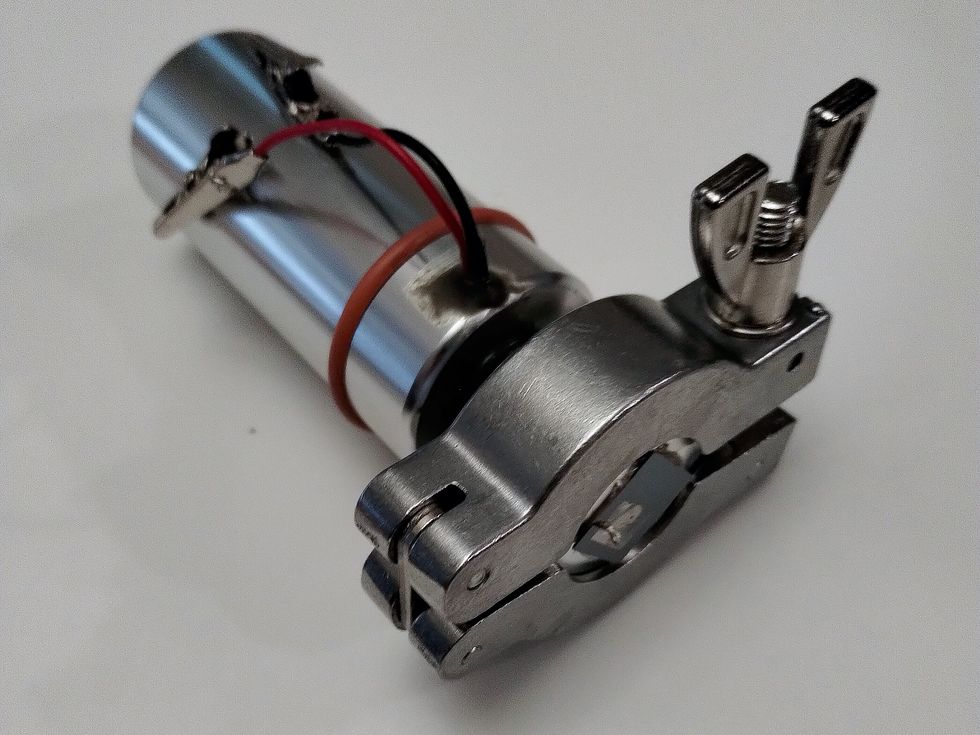

From Concept to Prototype

Currently, each chip contains only six tips, fabricated in a cleanroom at Oak Ridge National Laboratory. The next stage involves developing a full-scale version of the chip and constructing the surrounding thruster. Huffman anticipates that this will be a straightforward process, requiring integration of a few additional components.

“Two years from now, I can have a product that is sellable, probably,” Huffman projected, indicating that initial customers are likely to be small research teams willing to embrace new technologies despite the associated risks. The performance of Orbital Arc’s thruster could be particularly appealing for missions where cost efficiency is paramount.

Skepticism surrounding new propulsion systems remains, particularly regarding the lack of historical data to support the performance claims. Jonathan MacArthur, a postdoctoral researcher at Princeton University, expressed concerns about the necessity of empirical data to validate the startup’s assertions. “What remains to be seen is, okay, it’s cheap, but if I put diesel in my gas car because it’s on sale, that doesn’t necessarily bode well for the engine in my car,” he remarked.

Despite these reservations, there is potential for small-scale missions to adopt the new thrusters, particularly if they are offered at a discounted rate. Oliver Jia-Richards, a researcher at the University of Michigan, noted that recent successes by other startups in the electric propulsion sector may encourage customers to take a chance on innovative technologies.

Huffman’s vision extends beyond the initial thruster. He aims to develop a lightweight spacecraft bus, capitalizing on the efficiency of the new thruster design. “If you cut dry mass off of spacecraft, you gain exponential benefits in its performance because of the way the rocket equation works,” he explained. By integrating Orbital Arc’s thrusters, missions could potentially reduce the mass of solar panels and power supplies, enabling more ambitious projects, such as two-way human-rated missions to Jupiter.

As Orbital Arc continues to refine its technology, the implications for the future of space exploration and satellite operations could be significant, potentially transforming how missions are designed and executed.