BREAKING: A revolutionary AI-driven materials-genome strategy has been developed by researchers at the East China University of Science and Technology, significantly accelerating the design of ultra-tough polyimide films. This urgent breakthrough, published on September 2, 2025, in the Chinese Journal of Polymer Science, addresses critical challenges in aerospace and flexible electronics where polyimide films are essential.

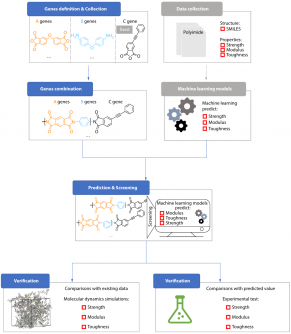

Polyimides are known for their thermal stability and insulation properties, yet achieving optimal mechanical performance has been a persistent challenge. Traditional methods often result in compromises between stiffness, strength, and toughness, making rapid development essential in today’s fast-paced technological landscape. The new AI-assisted approach integrates machine learning with extensive experimental data, enabling researchers to predict and optimize mechanical properties across 1,720 candidate structures.

The research team introduced a machine-learning model capable of accurately predicting three key mechanical parameters: Young’s modulus, tensile strength, and elongation at break. This model led to the identification of a novel formulation, PPI-TB, which outperformed established benchmarks in terms of mechanical metrics. The results revealed that PPI-TB achieved a remarkable modulus of 3.48 GPa, demonstrating superior toughness and strength compared to conventional systems.

“By translating polymer fragments into genetic-like descriptors, we can treat molecular design like decoding a genome,” said Prof. Li-Quan Wang, a leading author of the study. This innovative approach not only predicts performance but also identifies the chemical “genes” responsible for enhancing polyimide properties.

The study utilized Gaussian process regression (GPR) models trained on over 120 experimental datasets, achieving predictive accuracies of R² ≈ 0.70–0.74 for all three mechanical metrics. Molecular dynamics simulations confirmed the robustness of the findings, showing consistent performance between predicted and measured data.

These insights reveal key design principles that can revolutionize polymer innovation: conjugated aromatic structures enhance stiffness, while the incorporation of heteroatoms strengthens molecular interactions. Additionally, flexible silicon- or sulfur-containing units improve elongation, crucial for applications in microelectronics and aerospace composites.

The implications of this research are profound. By replacing years of experimental trial-and-error with predictive modeling and virtual screening, this AI-driven framework drastically reduces both development time and costs. Moreover, this scalable method could extend to other high-performance polymer classes, paving the way for lightweight, durable, and thermally stable materials that are vital to future electronic and aerospace technologies.

This breakthrough not only showcases the potential of integrating AI with materials science but also emphasizes the importance of rapid innovation in meeting the demands of modern technology. As researchers continue to explore these new avenues, the future of polyimide films—and their applications—looks brighter than ever.

Stay tuned for further updates on this developing story as the world watches how AI reshapes the future of materials science.